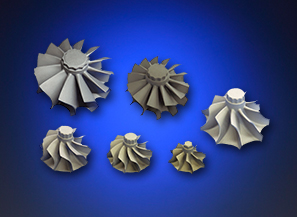

MIM (Metal-injection Molding)

TITANIUM SINTERED

PRODUCTS

Overview

Titanium (Ti) is a high-density strength, highly pliant, highly corrosive-resistant material, which in recent years is seeing ever-growing demand. On the downside, titanium is a difficult material to process and also an expensive one. We have applied the fruits of our 10-year track record in metal injection molding (MIM) technology in the development of MIM Ti sintering products.

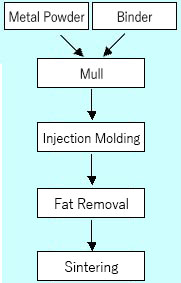

1. MIM Process

Figure 1: MIM Process Flowchart

2. Features of MIM Titanium Sintered Parts

(1) Configurations

In forging, it becomes possible to manufacture intricate, near-net shaped sintered products.

Figure 2: Example of MIM Ti Sintered Parts

(2) Features of Sintered Objects

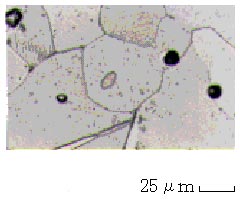

With a relative density of 97%, the structure of the sintered object is sufficiently advanced.

Figure 3: Microstructure

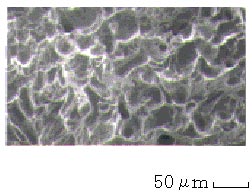

The mechanical features rival JIS 3-type welding materials (Chart 1). Furthermore, ruptures seen in stretch tests show ductile fatigue fractures that exhibit sufficient tractility.

| Chart1: P Properties of MIM Ti Sintered Parts | ||

|---|---|---|

| MIM Ti Sintered Parts | JIS3-type Standard | |

| Relative density (%) | 97 | 100 |

| Elasticity (NPa) | 600±20 | 480~620 |

| Growth (%) | 21±2 | ≧18 |

| 0.2% durability (NPa) | 310±39 | ≧345 |

| Hardness (Hmv) | 240±29 | - |

Figure 4: Fracture Surface

Now, with the Titanium alloy MIM, it has become possible to respond to the demand for high-strength products that have a degree of hardness.

Inquiries

- Industrial, Aerospace & Energy Materials Business Unit

- Contact Information