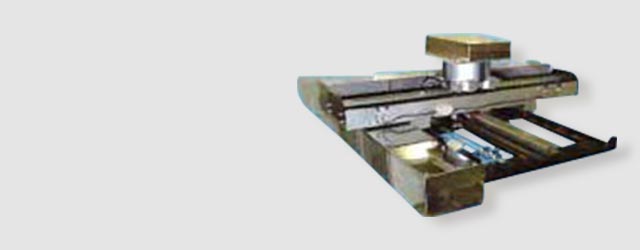

LINEAR MOTORS-DRIVEN LARGE XY θ STAGE

Overview

With the development of increasingly large-scale and sophisticated liquid crystal and plasma displays, demand for manufacturing equipment that is capable of high-speed, highly accurate positioning and with large-stroke specifications has grown.

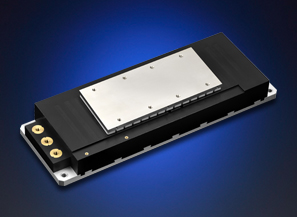

The linear motor directly driven large XYQ stage developed and commercialized by Hitachi Metals satisfies this demand and lays the groundwork for next-generation processing.

Features

For a high system performance, there has to be total performance of the motor unit, which generates thrust, the motor control unit, and the stage unit, which makes possible high-accuracy operation. This fully integrated system has the following merits.

1. High-speed, high-accuracy positioning: Because each axis is driven directly by a PM-type, direct current coreless coil motor using advanced rare-earth magnets, high-speed, high-accuracy positioning is possible even with long-stroke specifications. In addition, the system is simpler, smaller and lighter than others because it does not require a combination of coarse and delicate driving to achieve high speed without compromising accuracy.

2.Low-noise, low-dust emission: Because stage construction does not use ball screws, a low-noise structure is possible. And because there is no rotary section, which can cause oil mist to be scattered, dust levels are also kept down.

3.High reliability, low cost: Hitachi Metals standard linear motors are used in motor core sections with short delivery times.: Because reliability is high and parts are standardized, systems can be built very quickly and inexpensively.

4.In the case of Hitachi Metals general-purpose motor control units, it is possible to rewrite control programs using a microcomputer. Units can be custom-built to meet a wide range of preferences, including low- to high-speed operating ranges to positioning and velocity stabilization applications.

Basic Specifications

| Properties | Unit | Specification | |

|---|---|---|---|

| Motor thrust, torque | X axial | N | 200 |

| Y axial | N | 300 | |

| θ axial | N・m | 50 | |

| Stroke | X axial | mm | 1100 |

| Y axial | 1600 | ||

| θ axial | ±5 | ||

| Load | N | 588 | |

| Accuracy | X axial | μm | 30 |

| Y axial | μm | 30 | |

| θ axial | μm | 30 | |

| Repeatability | X axial | μm | ±1 |

| Y axial | μm | ±1 | |

| θ axial | μm | ±2 | |

| XY squareness | 400×600 | μm | 25 |

| Flatness | μm | 40 | |

| Straightness | X axis: Vertical | μm | 10 |

| Horizontal | μm | 10 | |

| Y axis: Vertical | μm | 10 | |

| Horizontal | μm | 10 | |

| Pitching | X axial | μm | 10 |

| Y axial | μm | 10 | |

| Yawing | X axial | μm | 10 |

| Y axial | μm | 10 | |

Inquiries

NEOMAX ENGINEERING Co.,Ltd.

Sales Department- Contact Information