Power Electronics

Materials Research Dept.

Responding to growing xEV*-related needs

Creating the future with power electronics materials

At the Power Electronics Materials Research Dept., we research and develop advanced components and materials with unique features. This includes silicon carbide (SiC), which is receiving attention as a next-generation power semiconductor, as well as silicon nitride substrates, soft magnetic components, and their applied products. Our R&D efforts in the high potential growth field of xEV technology are particularly focused on advanced components and materials that can help to achieve smaller, more efficient, higher output devices such as motors and inverters.

Aiming to contribute to a sustainable society

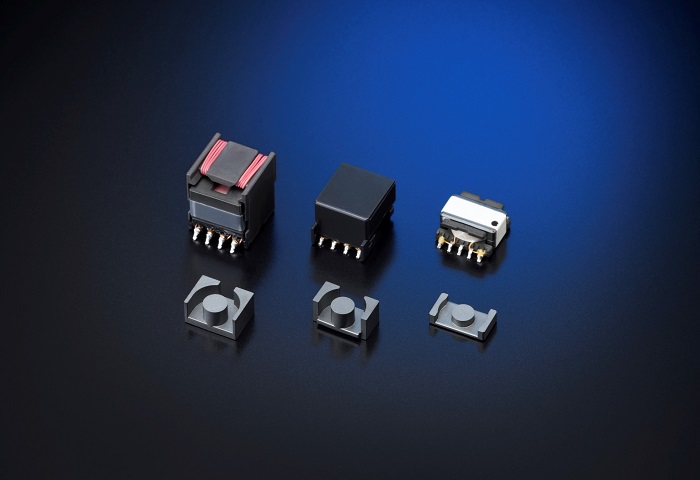

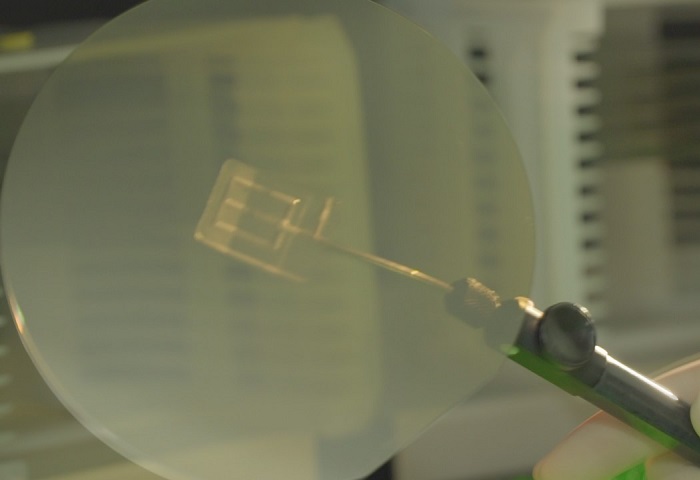

Demand for xEVs has been expanding worldwide recently, driven by growing awareness of the need for environmental conservation that is seen in strengthening regulations for CO2 emissions and fuel economy. To increase the driving range of xEVs, it is essential to improve the energy efficiency of their components. The Power Electronics Materials Research Dept. has commercialized low-loss soft magnetic materials, which build on our originally developed magnetic domain control technology and are available as the MaDC series. The department is also developing applied products from soft magnetic materials that are designed to contribute to increasing the efficiency and output of motors and onboard chargers. We also conduct R&D for advanced components and materials that can be used to make xEVs more efficient. These include developing silicon nitride substrates, which can efficiently release heat from power devices, and advancing the processes of polishing and epitaxial growth for SiC substrates, which are expected to serve as next-generation power semiconductors.

Yet another area of study at the department is advanced components and materials that drive the future development of industrial infrastructure. Examples include scintillator arrays for security applications that combine fast response and low cost to help improve the inspection speed and detection accuracy of baggage inspection equipment at facilities like airports, and isolators supporting 5G communications standards.

- Aplil 16, 2019

- Fraunhofer IISB and Hitachi Metals Develop New Technology to Enhance the Power Density in Compact On-Board Chargers

- January 2019

- Scintillator Array for Security(PDF:

)

) - October 2, 2018

- Developing a New Soft Ferrite Core Material with Low Core Loss in High-Frequency Range

- January 2018

- High Thermal Conductivity Silicon Nitride (Si3N4) Substrates(PDF:

)

) - December 21, 2017

- Development of New High-Robustness Ni-Zn-Based Soft Ferrite Material “ND57S”

- October 16, 2017

- Hitachi Metals Announces the Development of the FT-3K10Q Series, Common Mode Choke Coils/ Cores with High Impedance Using FINEMET® Nanocrystalline Magnetic Materials

- January 10, 2017

- Hitachi Metals Announces the Development of Block Cores of High-frequency Power Converters for Handling over 100 kW Using FINEMET® Nanocrystalline Soft Magnetic Materials and Metglas® Amorphous Metals

- April 4, 2016

- Hitachi Metals Creates New Soft Ferrite Core Material with Outstanding High-Frequency Characteristics

- January 2016

- Noise Suppression Core for Automotive Inverter, FINEMET® FT-3K50T VR Series(PDF:

)

)

Centering around its design technology for advanced components and materials, the Power Electronics Materials Research Dept. will strive to contribute to the creation of a sustainable society by offering diverse products and services conducive to the evolution of the xEV industry.

* Term referring to electric vehicles (EV), hybrid electric vehicles (HEV), and plug-in hybrid electric vehicles (PHEV).