Specialty Steel

Research Dept.

Knowing Our Materials Deeply

Aiming to Drive the Future

Exploring the Infinite Possibilities of Materials

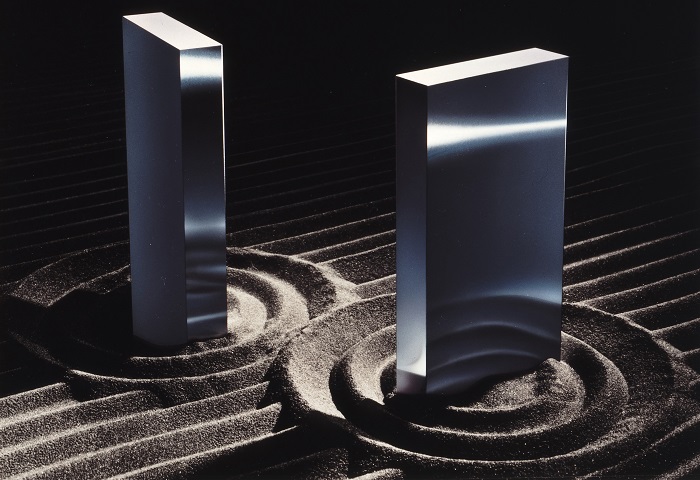

![[Photo]Metallurgical Research Laboratory](/e/resource/img/rad/rad_mrl/image-1.jpg)

Specialty Steel Research Dept.of Metallurgical Research Laboratory undertakes research and development (R&D) concerning specialty steels that play critical roles in a wide range of fields, including molds and tool steel, alloys for electronic products, materials for industrial equipment, and aircraft- and energy-related materials. The laboratory was founded in 1934 in Yasugi City of the Shimane Prefecture, where an ancient Japanese method for manufacturing iron has long been practiced. In this region, very rich in the history of steelmaking, the laboratory has now established its own tradition of specialty steelmaking. Directly adjoining Yasugi Works, one of Hitachi Metals’ major manufacturing sites, the laboratory is keenly engaged in R&D to draw out the infinite possibilities of metal materials with a clear grasp of our customers’needs.

Driving to Pioneer a New Era

Making specialty steel involves a number of multiple processes, such as basic steelmelting (refining, casting, and solidification), hot working (rolling and forging), heat treatment (heat transfer and phase transformation), and cold forming (rolling and drawing). Further, the characteristics of each metal are realized through the mutual influence of elements. Utilizing this understanding of material design and unraveling the complex relationships between elements, we are committed to creating new materials to respond to the demands of society.

The laboratory also conducts R&D concerning metal materials optimized for 3D printing. This new production field is attracting increasing attention. Also, soft magnetic components and materials to be used in the xEV* market, which is expected to expand in the near future are also considered. We are also pushing forward to create innovation by utilizing the expertise we have acquired over the years in the areas of alloy design, microstructure control, and process design, as well as combining CAE (Computer Aided Engineering) and MI (Materials Integration) into CMAP (CAE for Materials And Processes).

- December 18, 2017

- Manufacture Certification of Nickel Alloy Large Rotating Parts for Aircraft Engines

- October 20, 2015

- Put forward CMAP(CAE for Materials And Processes)

Specialty Steel Research Dept. continues to improve its technology development capabilities by exploring the possibilities of metal materials, aiming to address a variety of new challenges, including environmental protection and resource and energy conservation.

* Term referring to electric vehicles (EV), hybrid electric vehicles (HEV), and plug-in hybrid electric vehicles (PHEV).