Advanced Metals Division

Materials for industrial equipment

A history of innovation in advanced

metallurgical technology and materials

development

True to our tradition, we strive to consistently refine our material development capabilities. With the same intensity required to create tama-hagane—a high-value-added material produced by the tatara foundry method—we enhance the full luster of the materials we produce. While enhancing steel purity through stringent raw material selection methods, we continue to support the development of a wide range of industries by providing highly functional materials.

A list of Materials for industrial equipment

-

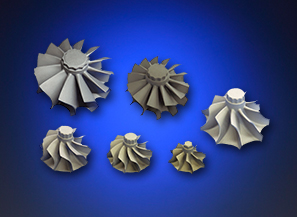

Turbine Wheel

for Turbo Charger

-

Materials For Use In Vanes & Engine Valves

-

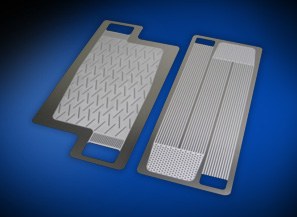

Metallic Interconnector Material For SOFC ZMG™232G10

-

Soft Magnetic Alloy with High Magnetic Flux Density Permendur

-

MIM (Metal-Injection Molding) Titanium Sintered Products

-

Metal Injection Molding (MIM) Cobalt Optical Communications Parts