Low Thermal-Expansion, Super Alloy HRA929 for Gas Turbines

Overview

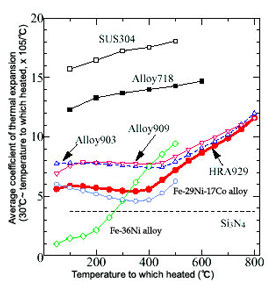

Fe-36Ni alloy and Fe-29Ni-17Co alloy are known for their generally low coefficients of thermal expansion. But, because they are not particularly strong, these alloys are not suitable for parts that are used in high-stress environments or exposed to high temperatures.

However, HRA929, which Hitachi Metals developed using alloy design techniques, has not only a low coefficient of thermal expansion but also [illegible] precipitation strength, enabling it to retain its strength in temperatures of up to approximately 650°C.

Furthermore, this alloy displays superior structural stability and ductility.

Features

-

Figure 1: Average coefficient of thermal expansion of various alloys

(1) Low coefficient of thermal expansion, close to those of Fe-Ni low thermal-expansion alloys.

-

Figure 2: Tensile strength of various alloys

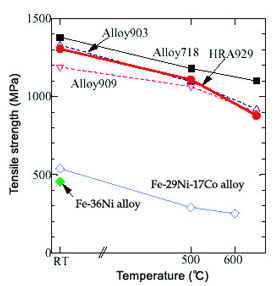

(2) Retains its strength at room and high temperatures at levels close to Alloy 718, which is known for its strength at high temperatures.

-

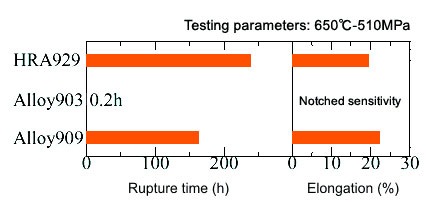

Figure 3: Creep rupture properties of various alloys

(3) High creep rupture strength does not show notched sensitivity.

Compared with conventional [illegible] precipitation-strengthened, low-expansion type Alloy903 and Alloy909, HRA929 has an even lower coefficient of thermal expansion, and creep rupture notch sensitivity and structural stability are improved.

Uses

Based on these benefits, HRA929 can be combined with ceramics or glass and used in parts that need to show high strength at room and high temperatures, and in gas turbine equipment requiring tight clearance at high temperatures.

The characteristics, photos, charts, rankings and evaluations of this web contents are representative value by our test data, it does not guarantee the quality of the product. This web contents are subject to change without notice.

Inquiries

- Aircraft- and energy-related materials

- Contact Information