Copper Alloys

Overview

Based on a long history of mining and smelting copper, we started the production of special copper alloys at Okegawa Works in 1944, and have been supplying our products to contribute a great deal to our world.

Our products have been supporting Japan’s growth in Automotive, Marine and a number of other industries. As an ISO 9001 certified company, Hitachi Metals ,Ltd. Okegawa Works is one of the principal suppliers of copper alloy rods, bars and other copper alloy products to various industries in automotive, heavy engineering, aviation, mining and other fields. The copper alloys we provide are lead-free (Restrictions of the use of Lead in E.U)*, and have high wear-resistance, excellent corrosion-resistance, and excellent fatigue-endurance.

The following list, for reference, is a comprehensive introduction of our copper alloys. Please note that each datum shown below is an typical value based on our experimental data, and is not guaranteed.

*MK603 contains Min.0.4-Max.3.0(wt%) Pb (lead).

Properties

Upper: Specification Lower: Reference

| Type | Material | Nominal Chemical Composition (wt%) |

Specific Gravity | Tensile Strength (N/mm2) |

Yield Strength (N/mm2) |

Elongation (%) |

Hardness |

|---|---|---|---|---|---|---|---|

| Special High strength Brass | MBA™2 | Cu-29Zn-3Al-3Mn | 8.0 | >539 640 |

- 335 |

>12 21 |

>80HRB 88HRB |

| MBA™5 | Cu-31Zn-5Al | 8.0 | >588 780 |

- 490 |

>12 15 |

>85HRB 94HRB |

|

| High strength Aluminum Bronze | AMB6* | Cu-10Al-4Fe-1Ni-1Mn | 7.6 | >685 740 |

- 195 |

>15 20 |

>170HB - |

| AMB104* | Cu-10Al-3Fe-5Ni-1Mn | 7.6 | >724 770 |

>380 470 |

>10 17 |

HB187-241 - |

*MBA is a registered trademark of Hitachi Metals, Ltd.

*AMB is an abbreviation of “Arms Bronze” (Our unique Aluminum Bronze) a trademark of Hitachi Metals, Ltd.

Lineup

A=Available, N/A=Not Available

| Material | Available Form | Characteristic and Application | |

|---|---|---|---|

| Extruded Bar | Forging | ||

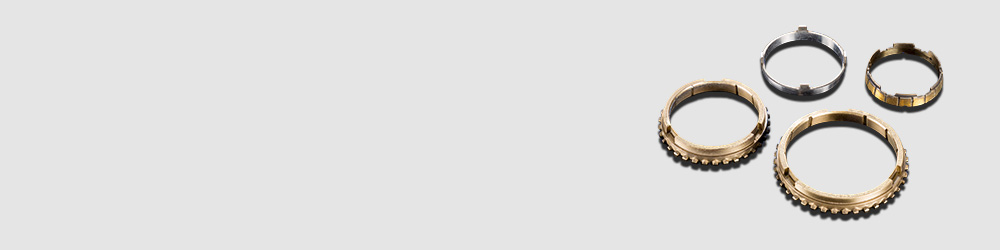

| MBA™2 | A | A | Synchronizer ring for cars, hydraulic parts, bearing and worm wheel. High wear-resistance. Lead-free. |

| MBA™5 | A | A | Synchronizer ring for cars. High wear-resistance. Lead-free. |

| MBA™52 | A | A | Synchronizer ring for cars. High wear-resistance. Lead-free. |

| MK40 | N/A | A | Propeller shaft and other parts for marine. Non magnetic, high corrosion resistance. Lead-free. |

| MK600 | A | A | Hydraulic parts, bearing. Lead-free. |

| MK603 | A | A | Hydraulic parts, bearing. High wear-resistance, excellent fatigue resistance |

| Arms Bronze™5 (AMB5) |

A | A | Bolts & nuts High corrosion resistance. Lead-free. |

| Arms Bronze™6 (AMB6) |

A | A | Machine parts High hardness, high wear-resistance, high corrosion resistance. Lead-free. |

| Arms Bronze™2 (AMB2) |

A | A | Worm wheel. High wear-resistance. Lead-free. |

| Arms Bronze™102 (AMB102) |

A | A | Tube sheet, bolt & nut. High yield strength, high corrosion resistance. Lead-free. |

| Arms Bronze™104 (AMB104) |

A | A | Machine parts. High corrosion resistance. Lead-free. |

| AMBX | A | A | Clip for trolley wire for railways. Lead-free. |

*MBA is a registered trademark of Hitachi Metals, Ltd.

*AMB is an abbreviation of “Arms Bronze” (Our unique Aluminum Bronze) a trademark of Hitachi Metals, Ltd.

Composition

(wt%)

| Material | Cu | Fe | Zn | Al | Mn | Ni | Others |

|---|---|---|---|---|---|---|---|

| MBA™2 | 63 | 29 | 3 | 3 | 2 | ||

| MBA™5 | 60 | 31 | 5 | 4 | |||

| MBA™52 | 62 | 30 | 4 | 4 | |||

| MK40 | 68 | 2 | 23 | 4 | 3 | ||

| MK600 | 59 | 36 | 1 | 3 | 1 | ||

| MK603 | 60 | 35 | 3 | 2 | |||

| Arms Bronze™5(AMB5) | 86 | 3 | 9 | 1 | 1 | ||

| Arms Bronze™6(AMB6) | 84 | 4 | 10 | 1 | 1 | ||

| Arms Bronze™2(AMB2) | 83 | 4 | 11 | 1 | 1 | ||

| Arms Bronze™102(AMB102) | 81 | 4 | 10 | 1 | 4 | ||

| Arms Bronze™104(AMB104) | 81 | 3 | 10 | 1 | 5 | ||

| AMBX | 86 | 3 | 9 | 1 | 1 |

*MBA is a registered trademark of Hitachi Metals, Ltd.

*AMB is an abbreviation of “Arms Bronze” (Our unique Aluminum Bronze) a trademark of Hitachi Metals, Ltd.

Available Specifications

| Material | JIS | ASTM/SAE |

|---|---|---|

| MBA™2 | ||

| MBA™5 | ||

| MBA™52 | ||

| MK40 | ||

| MK600 | SAE J463 674 | |

| MK603 | SAE J463 673 | |

| Arms Bronze™5(AMB5) | H3250 C6161 | |

| Arms Bronze™6(AMB6) | H3250 C6191 | |

| Arms Bronze™2(AMB2) | H3250 C6241 | |

| Arms Bronze™102(AMB102) | H3100 C6301 | |

| Arms Bronze™104(AMB104) | H3100 C6280 | ASTM B150 C63000 |

| AMB™X |

*MBA is a registered trademark of Hitachi Metals, Ltd.

*AMB is an abbreviation of “Arms Bronze” (Our unique Aluminum Bronze) a trademark of Hitachi Metals, Ltd.

Restrictions of the use of Lead in E.U (as of August 1st,2010)

Restrictions of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS Regulations)

- Enforcement:July 1st, 2006

- Restricted Substance:Lead, Mercury, Hexavalent Chromium, PBB, PBDE, Cadmium

- The following numeric categories apply:

- 1. Large and small household appliances.

- 2. IT equipment.

- 3. Telecommunications equipment

(although infrastructure equipment is exempt in some countries) - 4. Consumer equipment.

- 5. Lighting equipment—including light bulbs.

- 6. Electronic and electrical tools.

- 7. Toys, leisure, and sports equipment.

- 8. Medical devices (currently exempt)

- 9. Monitoring and control instruments (currently exempt)

- 10. Automatic dispensers.

- Exemptions:

- Lead as an alloying element in steel containing up to 0.35% lead by weight, aluminium containing up to 0.4% lead by weight and as a copper alloy containing up to 4% lead by weight.

Lead in lead-bronze bearing shells and bushes.

Restrictions of the use of hazardous substances including lead such as RoHS in EU, are also established in U.S.A(State regulations), China, Japan, Korea, etc.

Act on Recycling, etc of End-of-Life Vehicles

- Issued:October 21st, 2000

- Restricted Substance:Lead, Mercury, Hexavalent Chromium, Cadmium

- Exemptions:

- Lead as an alloying element in steel containing up to 0.35% lead by weight, aluminium containing up to 0.4% lead by weight and as a copper alloy containing up to 4% lead by weight.