- Automotive-Related Products / Electric Vehicle-Related Products Electric and Electronic Components

- Automotive-Related Products/Magnets and Motor-Related Products

- Magnets

Ferrite Magnets

Overview

Because these are oxide magnets produced by the powder metallurgy method, their residual magnetic flux density is relatively low, but they have the major advantage of high coercive force and are therefore not easily affected by the presence of demagnetizing fields.

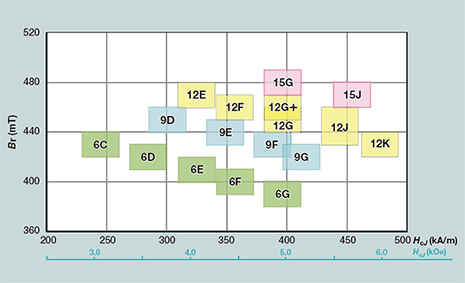

Positioning of Ferrite Magnets

Ferrite magnets use a wide range of materials with special properties. Especially at the high end of the performance spectrum, our magnet series are suitable for all kinds of applications.

HCJ and Br correlations of the various materials are shown in Figure 1.

Ferrite magnets may be customized upon request, within the indicated range of HCJ and Br characteristics.

In the interests of thorough quality control in each process, we have adopted measuring methods of the Magnetic Materials Producers Association (MMPA) of the United States and the Japanese Industrial Standard (JIS) for magnetic characteristics.

Features

High-Performance Ferrite Magnets NMF™ Series

Magnetic Characteristics

| Material code | Remanence Br |

Coercivity | Maximum energy product (BH)max |

|||||

|---|---|---|---|---|---|---|---|---|

| HCB | HCJ | |||||||

| (mT) | (kG) | (kA/m) | (kOe) | (kA/m) | (kOe) | (kJ/m³) | (MGOe) | |

| NMF-15G | 470-490 | 4.7-4.9 | 342-382 | 4.3-4.8 | ≧382 | ≧4.8 | 41.4-44.6 | 5.2-5.6 |

| NMF-15J | 460-480 | 4.6-4.8 | 342-382 | 4.3-4.8 | ≧440 | ≧5.5 | 39.7-43.0 | 5.0-5.4 |

| NMF-12E | 460-480 | 4.6-4.8 | 294-334 | 3.7-4.2 | ≧310 | ≧3.9 | 39.7-43.0 | 5.0-5.4 |

| NMF-12F | 450-470 | 4.5-4.7 | 318-358 | 4.0-4.5 | ≧342 | ≧4.3 | 38.2-41.4 | 4.8-5.2 |

| NMF-12G+ | 450-470 | 4.5-4.7 | 318-358 | 4.0-4.5 | ≧382 | ≧4.8 | 38.2-41.4 | 4.8-5.2 |

| NMF-12G | 440-460 | 4.4-4.6 | 310-350 | 3.9-4.4 | ≧382 | ≧4.8 | 36.6-39.8 | 4.6-5.0 |

| NMF-12J | 430-460 | 4.3-4.6 | 300-350 | 3.8-4.4 | ≧430 | ≧5.4 | 35.0-39.8 | 4.4-5.0 |

| NMF-12K | 420-440 | 4.2-4.4 | 300-350 | 3.8-4.4 | ≧462 | ≧5.8 | 33.4-36.6 | 4.2-4.6 |

| NMF-9D | 440-460 | 4.4-4.6 | 262-302 | 3.3-3.8 | ≧286 | ≧3.6 | 36.6-39.7 | 4.6-5.0 |

| NMF-9E | 430-450 | 4.3-4.5 | 310-350 | 3.9-4.4 | ≧334 | ≧4.2 | 35.0-38.1 | 4.4-4.8 |

| NMF-9F | 420-440 | 4.2-4.4 | 302-342 | 3.8-4.3 | ≧374 | ≧4.7 | 33.4-36.6 | 4.2-4.6 |

| NMF-9G | 410-430 | 4.1-4.3 | 294-334 | 3.7-4.2 | ≧398 | ≧5.0 | 31.8-35.0 | 4.0-4.4 |

| NMF-7C | 430-450 | 4.3-4.5 | 222-262 | 2.8-3.3 | ≧230 | ≧2.9 | 35.0-38.1 | 4.4-4.8 |

| NMF-7D | 420-440 | 4.2-4.4 | 254-294 | 3.2-3.7 | ≧270 | ≧3.4 | 33.4-36.6 | 4.2-4.6 |

| NMF-7E | 410-430 | 4.1-4.3 | 286-326 | 3.6-4.1 | ≧310 | ≧3.9 | 31.8-35.0 | 4.0-4.4 |

| NMF-7F | 400-420 | 4.0-4.2 | 278-318 | 3.5-4.0 | ≧342 | ≧4.3 | 30.2-33.4 | 3.8-4.2 |

| NMF-7G | 390-410 | 3.9-4.1 | 270-310 | 3.4-3.9 | ≧382 | ≧4.8 | 28.6-31.8 | 3.6-4.0 |

| NMF-6C | 420-440 | 4.2-4.4 | 230-262 | 2.9-3.3 | ≧230 | ≧2.9 | 33.4-36.6 | 4.2-4.6 |

| NMF-6D | 410-430 | 4.1-4.3 | 246-286 | 3.1-3.6 | ≧270 | ≧3.4 | 31.8-35.0 | 4.0-4.4 |

| NMF-6E | 400-420 | 4.0-4.2 | 278-318 | 3.5-4.0 | ≧310 | ≧3.9 | 30.2-33.4 | 3.8-4.2 |

| NMF-6F | 390-410 | 3.9-4.1 | 270-310 | 3.4-3.9 | ≧342 | ≧4.3 | 28.6-31.8 | 3.6-4.0 |

| NMF-6G | 380-400 | 3.8-4.0 | 262-302 | 3.3-3.8 | ≧382 | ≧4.8 | 27.0-30.2 | 3.4-3.8 |

| NMF-5C | 410-430 | 4.1-4.3 | 215-254 | 2.7-3.2 | ≧230 | ≧2.9 | 31.8-35.0 | 4.0-4.4 |

| NMF-5D | 400-420 | 4.0-4.2 | 254-294 | 3.2-3.7 | ≧270 | ≧3.4 | 30.2-33.4 | 3.8-4.2 |

| NMF-5E | 390-410 | 3.9-4.1 | 278-318 | 3.5-4.0 | ≧310 | ≧3.9 | 28.6-31.8 | 3.6-4.0 |

| NMF-5F | 380-400 | 3.8-4.0 | 270-310 | 3.4-3.9 | ≧342 | ≧4.3 | 27.0-30.2 | 3.4-3.8 |

| NMF-5G | 370-390 | 3.7-3.9 | 262-302 | 3.3-3.8 | ≧382 | ≧4.8 | 25.4-28.6 | 3.2-3.6 |

| NMF-3B | 400-420 | 4.0-4.2 | 175-215 | 2.2-2.7 | ≧190 | ≧2.4 | 30.2-33.4 | 3.8-4.2 |

| NMF-3C | 390-410 | 3.9-4.1 | 215-254 | 2.7-3.2 | ≧230 | ≧2.9 | 28.6-31.8 | 3.6-4.0 |

| NMF-3D | 380-400 | 3.8-4.0 | 246-286 | 3.1-3.6 | ≧270 | ≧3.4 | 27.0-30.2 | 3.4-3.8 |

| NMF-3E | 370-390 | 3.7-3.9 | 254-294 | 3.2-3.7 | ≧310 | ≧3.9 | 25.4-28.6 | 3.2-3.6 |

| NMF-3F | 360-380 | 3.6-3.8 | 246-286 | 3.1-3.6 | ≧342 | ≧4.3 | 23.8-27.0 | 3.0-3.4 |

| NMF-3G | 350-370 | 3.5-3.7 | 238-278 | 3.0-3.5 | ≧382 | ≧4.8 | 22.2-25.4 | 2.8-3.2 |

| NMF-D2 | 360-390 | 3.6-3.9 | 222-263 | 2.8-3.3 | ≧230 | ≧2.9 | 23.8-28.7 | 3.0-3.6 |

| NMF-D5 | 400-420 | 4.0-4.2 | 255-294 | 3.2-3.7 | ≧270 | ≧3.4 | 29.4-32.6 | 3.7-4.1 |

| NMF-D6 | 410-430 | 4.1-4.3 | 255-294 | 3.2-3.7 | ≧270 | ≧3.4 | 30.2-33.4 | 3.8-4.2 |

| NMF-D9 | 420-440 | 4.2-4.4 | 278-318 | 3.5-4.0 | ≧342 | ≧4.3 | 32.6-35.8 | 4.1-4.5 |

| NMF-D11 | 440-460 | 4.4-4.6 | 278-318 | 3.5-4.0 | ≧342 | ≧4.3 | 35.1-38.2 | 4.4-4.8 |

* Actual magnetic properties may be different from the ones shown above, depending on shape, size and manufacturing conditions.

Please contact your sales representative about other grades.

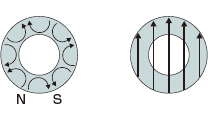

Ferrite Anisotropic Ring Magnets

Ferrite Anisotropic Multi-Pole Ring Magnets

| Types | Dry-pressing | Wet-pressing |

|---|---|---|

| Material | NMF-DM1 NMF-DM2 NMF-DM3 |

NMF-WM2 NMF-WM3 NMF-WM4 |

| OD(mm) | φ10~φ56 | φ10~φ30 |

Number of Poles * Orientation |

|

|

* On characteristics not listed on above table, please contact your sales representative.

Magnetic Characteristics

| Material code | Remanence Br |

Coercivity | |

|---|---|---|---|

| HCJ | |||

| (mT) | (kA/m) | (kOe) | |

| NMF-DM1 | 340 | ≧263 | ≧3.3 |

| NMF-DM2 | 360 | ≧302 | ≧3.8 |

| NMF-DM3 | 380 | ≧326 | ≧4.1 |

| NMF-WM1 | 250 | ≧239 | ≧3.0 |

| NMF-WM2 | 350 | ≧263 | ≧3.3 |

| NMF-WM3 | 370 | ≧302 | ≧3.8 |

| NMF-WM4 | 390 | ≧326 | ≧4.1 |

* Above numbers show material characteristics because B-H curves of actual multi-pole anisotropic magnets cannot be measured.

Products Catalog (PDF file)

Demagnetization Curve (PDF file)

Inquiries

Magnetic Materials Company

+81-3-6774-3408 +81-3-6774-3408- Contact Information