2022 News Release

Hitachi Metals, Ltd.

Developing Cathode Material Technology for Lithium-ion Batteries

Contributing to the Reduction of Greenhouse Gas Emissions

Hitachi Metals, Ltd. (“Hitachi Metals”) announced that it has developed technology achieving lithium-ion batteries (LIBs) with both an excellent cycle performance and high capacity even when using a reduced amount of cobalt (Co) for the cathode materials. The technology enables the reduction of greenhouse gas (GHG) emissions from the cobalt. Additionally, Hitachi Metals has developed a new manufacturing technology increasing the options for the raw materials of cathodes. Hitachi Metals will deploy the developed technologies as solutions to reduce the environmental load of the LIBs industry.

1. Background

LIBs are widely used in diverse fields including in mobile devices and hybrid and electric vehicles, as they characteristically have high energy density and enable miniaturization and weight reduction. Demand for LIBs is expected to grow rapidly, especially for electric vehicles.

To ubiquities electric vehicles, it is important to extend their driving range and total driving distance. The key to success is cathode materials that achieve LIBs with both an excellent cycle performance and high capacity. The cathode materials of LIBs for automobiles have commonly been ternary layered materials*1 that enable excellent cycle performance and high capacity. Achieving a high capacity of the ternary layered materials, there is a method of increasing the amount of the main element nickel (Ni) contained to increase the amount of lithium ions for insertion/desorption*2. However, there is an issue with this method: The higher Ni content reduces charge and discharge cycle resistance, resulting in shortened battery service life. There is another issue connected to cobalt, which is a precious resource as the main ingredient of cathode materials. Cobalt involves enormous GHG emissions when it is used as a raw material in the production of LIBs, contributing to an increase in GHG emissions.

2. Outline

-

Photo: Cathode materials for lithium-ion batteries

Photo: Cathode materials for lithium-ion batteries

Hitachi Metals has developed a technology for the cathode materials of LIBs which employs an original solid state reaction method*3 that fully uses powder metallurgy technology during synthesis to achieve the two features below.

(1) Achieving both an excellent cycle performance and high capacity through control of microstructure

(2) Increasing raw material options

The technique for controlling microstructure helps prevent the deterioration of the crystal structure accompanied by the charge and discharge cycle. It enables the Ni content to Cathode materials for lithium-ion batteries be increased to 90% when it had previously been around 80% in general. This enables LIBs to have a long battery service life even with a high capacity. In addition, now the cobalt content can be reduced 80% from the previous Hitachi Metals product. Cobalt has been an indispensable component of cathode materials capable of stabilizing the crystal structure (Reference on Page 2).

There are more options for the starting materials used for manufacturing cathode materials*4, and it is possible to reduce the GHG emissions from raw materials by using the solid state reaction method that enables the use of materials that are not water-soluble. Hitachi Metals will provide the developed technologies as solutions to customers engaging in the mass production of cathode materials/LIB development.

The newly developed technologies will be presented at the Automotive Engineering Exposition 2022 at PACIFICO Yokohama starting on May 25.

Hitachi Metals will provide customers with leading-edge technologies for the realization of carbon neutrality as a high-performance material manufacturer that contributes to the establishment of a sustainable society.

Contact for customers:

Global Research & Innovative Technology center, Hitachi Metals, Ltd.

Click Here

Contact for press:

Corporate Communications Dept., Hitachi Metals, Ltd.

hmcc.sa@hitachi-metals.com

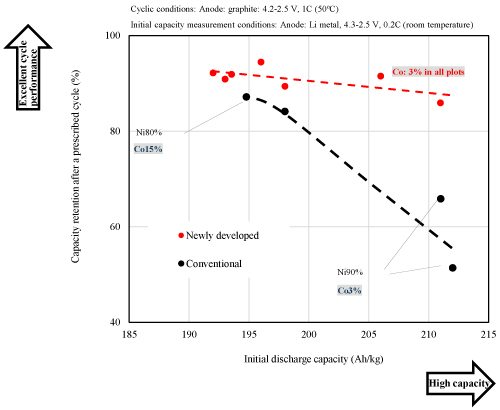

■Reference: Electrochemical properties of cathode materials

(Technologies developed by Hitachi Metals indicated by a red broken line and red dots)

Excellent capacity retention achieved even with the high Ni content (90%) composition.

Cobalt content can be reduced from 15% to 3%

by increasing the ratio of Ni (compared with Hitachi Metals' conventional product)

- *1 Ternary layered materials

- : Layered structure materials containing the main components Ni, Co, Mn, and Al.

e.g., NCM (based on Ni, Co, Mn), NCA (based on Ni, Co, Al) - *2 Insertion/desorption

- : Movement of ions in the method of generating electricity used by LIBs.

Ions are desorbed from the cathode materials and inserted into the anode material during charging, and they are desorbed from the anode material and inserted into the cathode materials during discharging. - *3 Solid state reaction method

- : A manufacturing method based on the powder metallurgy process that involves the pulverization and mixing of raw materials containing lithium and metals that are the elements constituting the final result and then baking them after granulation to trigger the reaction.

Cathode materials are manufactured by chemically synthesizing precursor metal hydroxide particles, mixing them with raw material lithium powder and baking them without pulverization or granulation. - *4 Starting material

- : Raw material used as the starting point necessary for the initial chemical reaction in the generation of chemicals for cathode materials.