2012 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

The lineup of copper alloy target materials for LCD panels and touch-panel wiring has become available.

Hitachi Cable has released the lineup of copper alloy target materials using the copper manganese alloy developed by Tohoku University for wiring in the LCD panels and touch-panels of smartphones.

The target materials are manufactured by melting metal and shaping it into plates or disks by sintering or rolling. They are used to form metal membranes on the surfaces of LCD panels and semiconductors with plasma sputtering.

In LCD panels, copper target materials are used as a wiring material in TFT (thin film transistors) on glass surfaces. In recent years, there has been increasing demand for copper target materials to enable LCD panels to become larger size, higher resolution and higher switching speed compared to LCD panels using aluminum because of copper's lower electrical resistance than aluminum. In addition, copper / copper alloy target materials are used as a wiring material for rims of touch-panels for smartphones and such to gather signals from touch-sensors. Copper / copper alloy target materials which can deliver a higher wiring density than silver paste have been adopted in many products to produce finer rims.

Since 2006, we have been using oxygen-free copper manufacturing technology to produce pure copper target materials with purity of more than 99.995%. Major LCD panel manufacturers in Japan and overseas have already adopted our copper target materials and have been using them in various products such as LCD televisions, computer screens, mobile phones, and smartphones.

When using copper as a wiring material for LCD panels and touch-panels, a base layer must be formed using molybdenum, titanium or their alloys to ensure adhesiveness with the glass. However, as the increasing demand for low-cost LCD panels cost of base layer target materials need to be low.

In order to respond to such a need, we have released a lineup of copper manganese alloy targets developed by Tohoku University for wiring in LCD panels and touch-panels, applied to LCD televisions and smartphones.

The addition of a small amount of manganese to oxygen-free copper has increased contact and adhesiveness with amorphous silicon semiconductors and transparent amorphous oxide semiconductors made with InGaZnOx. Because it delivers the equivalent adhesiveness to conventional molybdenum or titanium, it can be used as a base metal underneath pure copper for wiring. It can also be used as a cap metal for copper wiring of touch-panels because its oxidation resistance is superior to that of pure copper.

The copper manganese target material makes it possible to manufacture low-cost and highly reliable copper wiring structures because manganese has higher general versatility than molybdenum and titanium.

We will continue our efforts to develop products to respond to more needs and expand the lineup of copper alloy target materials.

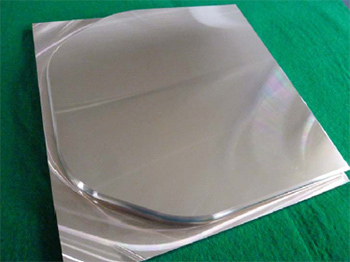

Appearance of a copper alloy target

An example of the use of copper manganese target in TFT

Data on the adhesiveness of copper manganese

| Condition after film formation | No processing |

|---|---|

| Heated at 200°C for 30 min. | 100% |

| Heated at 300°C for 30 min. | 100% |

| Residual rate after a tape test | 100% |

Oxidation resistance data