2009 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Introduction of new facilities for superconducting cables for ITER

Hitachi Cable, Ltd. has announced the introduction of new production facilities to Hitaka Works, one of the major production bases for wires and cables of Hitachi Cable, to manufacture the superconducting cables utilizes for ITER (International Thermonuclear Experimental Reactor), aiming at the full-scale operations in August 2009.

With little carbon dioxide emissions and minimal environmental affect, the fusion energy has been expected as a clean energy in next generation. To demonstrate the scientific and technological feasibility of the fusion energy for peaceful application, the ITER project, a large-scaled international project whose goal is to develop the first experimental fusion reactor in human history, is currently proceeding with the cooperation of seven partners: Japan, EU, Russia, USA, Korea, China, and India. The reactor is scheduled to be commenced in its operation in 2018. In Japan, the Japan Atomic Energy Agency (hereinafter referred to as JAEA) functions as a liaison to the ITER Organization by handling the manufacture of components and the provision of personnel required for the project.

Within the experimental reactor of ITER, plasma, which is superheated to over 100 million degrees, is restrained by an intense magnetic field to initiate nuclear fusion. A superconducting coil called as toroidal field coil will be used to generate a magnetic field continuously over a long period. As the first procurement for the ITER project, Hitachi Cable was granted a 2-billion-yen order from JAEA in March 2008 covering the superconducting wires (Nb3Sn) and superconducting cables intended for use in the toroidal field coils. To ensure consistent quality and to promote the mass production, the manufacturer has introduced some wire-stranding machines at the Hitaka Works to enhance the ITER superconducting cable production.

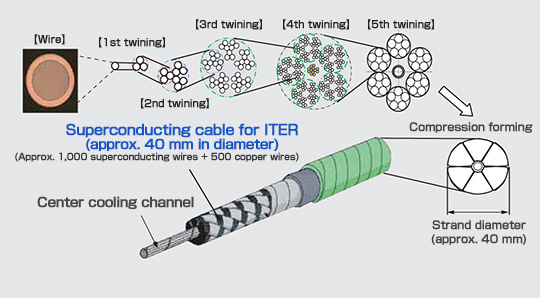

A superconducting cable is composed of two different materials of wires: superconducting wires (approx. 1,000) and copper wires (approx. 500) twisted together with circular form having approx. 40 mm in diameter. The cable is capable of carrying a 68 kA current in an intense magnetic field of 12 T (tesla). Hitachi Cable has installed a state-of-the-art wire-stranding machines for the process of twining these different types of wires, that will boost the productivity and ensure higher-quality superconducting cables. Production using the new equipments will be launched in August 2009, until the delivery of 4,500 m cables by 2010.

Hitachi Cable Group remains dedicated to expanding and strengthening its superconductor operations in further pursuance of research and development linked to developing the clean energies for next generation.

Overview of Hitaka Works

| Address | : | 1-1, Hitaka-cho 5-chome, Hitachi, Ibaraki |

| General manager | : | Shunsuke Kawabata |

| Number of employees | : | 1,004(as of the end of March 2009) |

| Site area | : | 626,000m2 |

| Building area | : | 270,000m2 |

| Main products | : | Telecommunication cables, Insulated wires, Special cables for nuclear power plants, Wires and cables for transportation |

Reference: Illustration of the structure of the superconducting cable

(As the courtesy of JAEA)

Reference: Website of ITER: the International Thermonuclear Experimental Reactor