2007 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Hitachi Cable to strengthen copper strip production facilities

Hitachi Cable, Ltd. announced plans to invest approximately six billion yen in its copper strip production facilities at Tsuchiura Works, its production facility for copper products. Plans call for the enhanced facilities to go online during Fiscal 2010.

Previously, in January 2006, Hitachi Cable announced plans to invest 2.5 billion yen to strengthen its copper strip production facilities. This latest decision expands earlier plans, further reinforcing these facilities to meet anticipated market and technological trends for 2010 and beyond. In addition to expanding copper-strip production capacity from current levels of 4,600 t/month to 5,200 t/month, by establishing high-performance, high-quality production facilities, the investment will enhance the company's copper strip operations, revolving around products with high levels of added value.

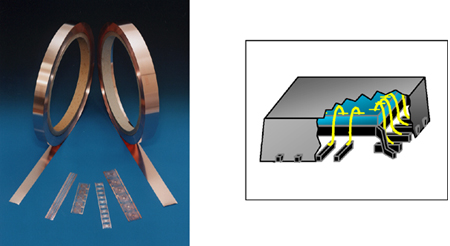

Hitachi Cable's copper-strip business is based on dual-gauge copper strips, copper alloy strips, and rolled copper foil. The capital investment just announced specifically targets enhancements in copper alloy strip operations.

In the field of lead frames- key application of copper alloy strips-rojections call for marked growth in the market for compact packages such as quad flat package non-lead (QFN) packages. Copper alloy strips even thinner than those currently available, providing improved quality and strength, are in demand for use as materials. Demand is also mounting in the field of connectors for the development of new alloy strips with high strength and electrical conductivity.

To meet this demand, Hitachi Cable has broadened plans previously announced last January. Earlier plans called for installing additional bell annealing furnaces and renovating the company's continuous annealing furnaces. The changes to be implemented under the latest plans call for the adoption of new continuous annealing furnaces and a new project phase involving the remodeling of existing rolling mills and adoption of new rolling mills. These projects will strengthen the foundations of the entire manufacturing process.

The new rolling mills being proposed are finish rolling mill with multiple rolls intended to achieve superior copper-sheet form control. The new continuous annealing furnaces will achieve the high-temperature solutions needed to produce copper alloy strips of high strength and electrical conductivity. Adopting this equipment will increase rolling efficiency and further improve quality.

The new equipment Hitachi Cable plans to adopt as part of its revised plans requires a minimum lead time of two years. For this reason and to meet the growing demand in semiconductor materials and connectors projected for 2010 and beyond, the company will accelerate implementation of its mid- to long-range capital investment plans.

The investments are expected to enhance productivity and hasten the shift to high-value-added products, as well as expand copper strip operations while stabilizing and improving quality.

Overview of Tsuchiura Works

| Address | 3550 Kidamari-cho, Tsuchiura, Ibaraki Pref. |

|---|---|

| General Manager | Shigeru Yumino |

| Employees | 779 (as of March 31, 2007) |

| Site area | 552,000m2 |

| Building area | 134,000m2 |

| Major products | Copper strips, copper tubes and copper products for electrical use |

Left: High strength copper alloy strips

Right: QFN package diagram

Hitachi Cable, Ltd. Tsuchiura Works