2006 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Hitachi Cable has established manufacturing techniques for

ultra-fine copper-alloy wire and micro coaxial cable based on this wire

Hitachi Cable, Ltd. announces that it has developed an ultra-fine copper alloy wire that exhibits both high conductivity and high strength at a diameter of only 13 micrometers. Hitachi Cable has also established manufacturing techniques for micro coaxial cables utilizing this copper alloy wire as the conductor.

A micro coaxial cable consists of an inner conductor strung from several conductor wires, an insulator, an outer conductor, and a jacket. Micro coaxial cables are highly flexible, compact, and noise resistant, and provide high transmission rates. They are used in diverse products including internal wiring for electronic devices such as notebook PCs and mobile phones as well as probe cables for ultrasonography. As these products become smaller and more advanced, the demand for micro coaxial cables with smaller diameters is rising.

In order to produce micro coaxial cables with smaller diameters, it is necessary to make the component materials-the conductors, insulator, and jacket-thinner. As electric resistance increases when the conductor is made thin, the conductor material itself needs to have high conductivity. At the same time, it must have a high strength to endure repeated bending and twisting.

The Hitachi Cable Group has been doing business in all aspects of micro coaxial cable manufacturing, from the development of a copper alloy meeting the requirements for thinner conductors to the production of cables, including the casting, drawing, and fabrication. We have already established practical production of a copper alloy wire with a diameter of 16 micrometers utilizing a copper-tin alloy (NN alloy) exhibiting improved strength over pure copper. We have also commercialized a 46AWG *1 (diameter: 0.048 mm) micro coaxial cable ahead of other manufacturers, using the wire as the inner conductor.

To respond to the demand for micro coaxial cables with smaller diameters, Hitachi Cable Group recently developed a new copper-silver alloy (S-MF-AG alloy). We have also improved our casting and drawing techniques, metal crystalline structure control techniques, and processing and heat treatment techniques. As a result, Hitachi Cable has succeeded in developing a new ultra-fine copper alloy wire with a diameter of 13 micrometers with higher conductivity and strength than conventional NN alloy wire. We have also established the techniques for its mass production.

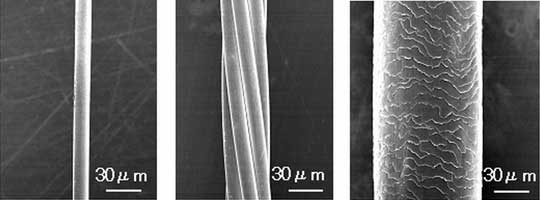

(See [External appearance of conductor].)

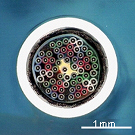

Further, by using this ultra-fine wire as the inner conductor and improving the micro-extrusion technique for the insulator and the jacket, we have established the manufacturing techniques for a 48AWG (diameter: 0.039 mm) micro coaxial cable. (See [Cross-section of micro coaxial cable].)

The Hitachi Cable Group will utilize this 48AWG micro coaxial cable in the probe cable for ultrasonography used in medical diagnosis and will start sales of the cable.

A probe cable consists of many micro coaxial cables acting as signal lines.

(See [External appearance and cross-section of medical probe cable].) As ultrasonography equipment improves, the number of signal lines and the external diameter of the cable tend to increase. At the same time, there is high demand for thinner cables, both to respond to the increase in the number of cases requiring that the cable be inserted into the body and to improve operability.

Application of this 48AWG micro coaxial cable to the endoscope probe cable can significantly reduce patient discomfort when the cable is inserted into the body. For example, when 60 micro coaxial cables are used, the external diameter of the probe cable is 30 percent smaller with 48AWG cables than with 46AWG cables.

The Hitachi Cable Group hopes that probe cables utilizing these micro coaxial cables with superior electric and mechanical characteristics will contribute to the continued refinement of medical equipment and less-invasive medical techniques. We are also considering various other applications for this ultra-fine alloy wire and micro coaxial cable, the manufacturing techniques of which we have recently established.

We expect that demand for micro coaxial cables for use in the internal wiring of notebook PCs and mobile phones and in medical probe cables will increase by approximately 50 percent in fiscal 2009 compared with fiscal 2007. The Hitachi Cable Group will add the 48AWG micro coaxial cable to its product line-up and will set a goal of increasing the net sales of micro coaxial cables from the expected approximately 4,000 million yen in fiscal 2007 to approximately 10,000 million yen in fiscal 2009.

| *1 | AWG (American Wire Gauge) is a number that indicates the size of a conductor. The larger the number, the smaller the diameter of the conductor. |

Conductor characteristics

| Conductor | Conductor structure (Number of strands/ diameter in mm) |

Breaking strength (MPa) |

Conductivity (%IACS) |

|---|---|---|---|

| S-MF-AG Alloy wire |

7/0.013 | 950 | 86 |

| NN Alloy wire | 7/0.016 | 900 | 75 |

External appearance of conductor

a) Single wire conductor (diameter:0.013 mm)

b) Strand conductor (7 wires/diameter:0.013 mm)

c) Human hair, for comparison (diameter: 0.08 mm)

Cross-section of micro coaxial cable

a) Developed product (48AWG)

b) Conventional product, for comparison (46AWG)

External appearance and cross-section of medical probe cable

External appearance of medical probe cable

Cross-section of medical probe cable