2001 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Mass-Producing Copper Backing Plates Using Friction Stir Welding

Hitachi Cable, Ltd. has successfully developed friction stir welding (FSW) technology for copper. Using this new technology, they start mass-production of copper backing plates, which are the support panels of target materials in sputtering machines. Leveraging the special features of this new product, Hitachi Cable aims for fiscal 2001 sales of copper backing plates to be approximately 600 million yen.

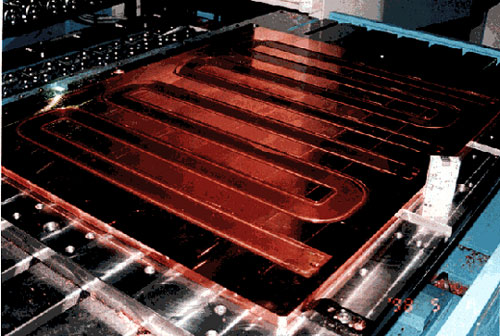

Sputtering is a very popular process of thin film formation for semiconductor devices, media discs and LCDs. In the sputtering machine, the backing plate (illustration 1) is not only a support panel of target materials, but also an electrode and a cooling system by water channels in the plate. To produce the backing plate, grooves are dug into a metal board to create a water channel, and metal covers are welded over the grooves. And the surface is finished being leveled out by face-mill process. The welding of the covers on the grooves substitutes the new technology, FSW, for the conventional electron beam welding

This new method has several advantages over the conventional method:

1) Less thermal distortion because of no melting of the materials,

2) This less distortion leads us to easier planing of the surface after welding,

3) Inexpensive apparatus.

In these years, increasing demand of large-scale LCD displays for TV-sets requires large-scale backing plates with high-quality surface. The largeness degrades the surface accuracy of the plates, especially because of distortion during the welding process. It was necessary to find a suitable new welding process as quickly as possible.

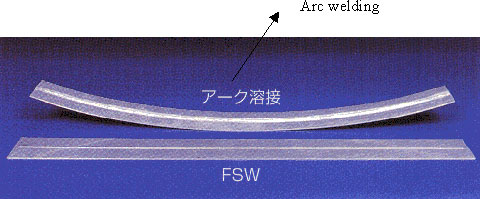

FSW, a breakthrough process, was invented by the U.K. research and technology organization TWI (The Welding Institute) Ltd., in 1991. In FSW, a rotating screw tool is inserted between two abutting materials to stir and to mingle the materials each other (illustration 2). This method of welding is completely different from such conventional methods as electron beam welding, arc welding, or laser welding, in that it does not melt materials during the welding process. As a result, there is little distortion or warping in the materials. Until now, FSW had been used for welding of aluminum alloys in railway cars and boats, and using it with copper alloys was still in the research stage. However, as a result of our collaborative research in tools and welding conditions with Hitachi, Ltd., Hitachi Cable has succeeded in using FSW for copper and copper alloys. With this, Hitachi Cable became the first company in the world to use FSW to mass-production of copper backing plates. Hitachi Cable and Hitachi, Ltd., have jointly applied for a patent on the application of FSW for manufacturing copper backing plates.

Our copper backing plates have a variety of special features. First of all, they have improved dimensional accuracy, because the welding process takes place at relatively low temperatures. This means that there is little material distortion (illustration 3). In addition, because materials are not melted during the welding process, the welded areas do not have a cast structure, but rather a refined structure. Therefore, they are mechanically superior to the conventional process (illustration 4). Leveraging these special features, Hitachi Cable plans to develop this technology for use in production for such growth areas as LCD displays, semiconductor devices, and CD/DVDs.

Production will take place at our subsidiary Hitachi Copper Products, Ltd., and Hitachi Cable will handle sales.

| *1 | Sputtering machines. Sputtering (illustration 5) is a fabrication method of thin films on a baseboard by having particles hit a target material. The backing plate is the support panel of the target materials. |

Explanation of terms:

Cast Structure: The microstructure of metals and alloys that have melted and solidified.

Refined Structure: The microstructure resulting when a cast structure is rolled or otherwise processed.

A Profile of Hitachi Copper Products, Ltd.

Location:3350 Kidamari-Cho, Tsuchiura City, Ibaraki Prefecture

Capital:80 million yen (as of March 31, 2001)

Sales: 3,499 million yen (for the period ended in March 2000)

Major shareholders:Hitachi Cable, Ltd. (100%)

Employees:195 (as of March 31, 2000)

April 5, 2001

Hitachi Cable,Ltd.

illustration 1 overview of a Backng Plate

illustration 2 Friction Stir Welding

April 5, 2001

Hitachi Cable, Ltd.

illustration 3 Comparison of Distortion between by arc welding and FSW method

*FSW(Friction Stir Welding)

illustration 4 Comparison of mechanical properties between by FSW and other methods

illustration 5 Spattering