1999 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Introducing the sale of the 'Komaki Series', enamel wires for use in highly efficient motors

We have started selling the 'Komaki Series', enamel wires for use in highly efficient

motors.

In recent years with environmental problems and the increasing inclination to save resources, a variety of miniaturized and more power saving electrical appliances are being promoted. Especially because of revisions in energy saving laws (laws related to the rationalization of the use of energy), starting with air conditioning, there is a pressing need to cut the amount of electric power used in household electrical appliances.

Also, with the tendency to reduce exhaust fumes, HEV (Hybrid Electric Vehicle) and other electric vehicles have become more practicable. Under such conditions environmentally friendly household electrical appliances and vehicles become key issues, and it is being demanded that even the motors used are to be highly efficient.

There are a variety of ways to make motors highly efficient and each motor manufacture's design concept is different, they all think that the high space factor of the magnet wire coil is one of the ways to make motors highly efficient. By using a magnet wire coil with a high space factor: it is possible to realize a miniaturized motor and design a highly efficient motor with low iron and copper loss. However, if the space factor exceeds 70% with the usual enamel wires used in motors, when they are inserted into the guide and slot (the slot of the core in which the enamel wires are inserted), external damage occurs easily because of high stress on the enamel wires' surface membrane. As a result of this it is easy for a layer short fault etc. to occur and there are problems like a loss of motor reliability.

So, with our uniquely developed special coating on the surface of the enamel wires, we have good lubrication and high abrasion resistance. The result of this is that it has been possible to develop and practically use the 'Komaki Series', enamel wires for highly efficient motors which have a high space factor.

Also due to the superior lubrication of the 'Komaki Series', it can raise the space factor level to 70-75%, which had a level of 55-65% so far. Furthermore, because of high abrasion resistance, even if the magnetic wire coil is in a severe condition, it is difficult for damage to occur, it is also possible to preserve excellent insulation efficiency etc. and high reliability can be maintained.

We are hoping that the 'Komaki Series' will be used in following 2 areas: home electrical & manufacturing areas (chlorofluorocarbon apparatus, all-purpose motors, and heat resistant apparatus) and the electrical equipment for automobiles market (EV, HEV and electrically powered power-steering).

As one of our future core products in the magnet wire sector, the product line-up of the 'Komaki Series' enamel wires for use in highly efficient motors will be expanded and perfected.

We intend to try hard to develop business in anticipation of market needs on energy saving.

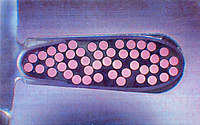

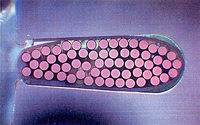

N.B. The space factor represents the ratio of the cross-sectioned area that the enamel wires occupy in the slot.

the space factor

-

55% the current model

-

70% KOMAKI