1998 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Introducing the development of a Mechanical Splice which can splice 4-fiber Ribbon with low loss

Recently we, in collaboration with NTT, have developed this Mechanical Splice which by not using a commercial electrical source can quickly splice 4-fiber Ribbon with low loss.

Up to now the splicing of an optical fiber has been done by dissolving the optical fiber with electrical discharge & splicing it, using the so called Arc Fusion Splice method. The advantage of this method is that it is highly reliable for uncommonly low loss in the splicing area, but the splicing tool is comparatively expensive & a power source is necessary. On the other hand with the Mechanical Splice which is fix linked to the optical fiber, cost is low & splicing is easy, but in the past their level could not be ensured to be as reliable as the Arc Fusion Splice.

Now, NTT are in the middle of promoting their 'π System' which will bring optical fibers close to all homes & therefore the business of splicing optical fibers is expected to rapidly increase.

Amidst such conditions we saw it necessary to develop a Mechanical Splicer that had advantages such as: not requiring an electrical source, being low cost as well as having superior reliability because of low loss.

We already developed a Mechanical Splice for use with a single optical fiber two years ago, again in collaboration with NTT. We overcame the usual problem area of poor reliability associated with Mechanical Splices, & were able to realize highly reliable splicing with low loss.

With the pressure of a Clamp Spring, the optical fiber was firmly fixed to the groove in a V - shaped circuit board (V-groove) & because of this, was very accurately linked. Furthermore, by having the linking parts filled up with index matching material (a type of silicon grease), low loss splicing with loss as low as the average Arc Fusion Splice was realized.

However, in 4-fiber ribbon, getting high accuracy in all 4 optical fibers was especially difficult. By making all material parts better & adding improvements, we have now successfully developed a Mechanical Splice which splices with the same high accuracy to all 4 Optical Fibers.

Also, in order to make splicing easier with our Mechanical Splice, splicing tool substances using batteries, such as 'Hot Stripper' etc. & other such tools have been originally developed for this particular purpose.

The 'Hot Stripper' is a removal tool which heats the UV curable resin coating on the 4 Cores & peels it away. In the past a working electrical power source was used but now because the product that we have developed uses a dry battery & is cordless it is: small scale, light weight (35 mm x 40 mm x 155m, about 350g), coupled with the fact that its workability has rapidly advanced. Also as it saves on electrical power it can work to remove the coating sufficiently.

It is expected that our Mechanical Splice will be well suited to the whole optical system; as with the 'π System' & FTTH (Fiber To The Home) etc. the construction of optical fiber information systems are progressing, alongside this easy & low cost splicing is beginning to be requested by the optical access network.

Please see listed below the main characteristics of the Mechanical Splice for use on 4-fiber ribbon that we have recently developed:

| 1. | Electrical power source is not necessary. |

| 2. | Low loss splicing (average: less than 0.1 dB) possible quickly (about 4 mins) |

| 3. | Even according to the very strict Bellcore reliability test (high temp, high moisture test 60degrees centigrade, 95% etc.) deterioration of special characteristics such as loss increase etc. were extremely small thus showing superb reliability. |

| 4. | Compact & light weight. The dimensions of the Mechanical Splice are: 40 mm × 4 mm × 4 mm, & it weighs about 2g. The heat shrink tube used to protect the splicing part is about the same size as in the usual Arc Fusion Splice. The exclusive splicing tool is 200 mm × 120 mm × 50 mm, & about 800g, significantly smaller & lighter, not to mention cheaper than the Arc Fusion Splice ( 150 mm × 150 mm × 150 mm, & 3 kg) |

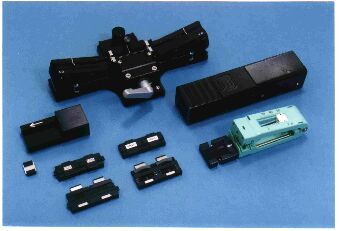

Structure of the Product

1 groove (single optical fiber use) or 4 grooves (4-fiber ribbon use), plastic circuit board with V groove.

3 pressure board pieces for pressing the fiber against the V groove.

The holding & provision of pressure to these circuit boards total of 5 parts.

Splicing process

The Mechanical Splice is a compact, light weight exclusive tool to use: a wedge is put in create a space between the V groove circuit board & the pressure board. The splicing fiber is linked & inserted into this space from both sides & the wedge is taken out.