2004 The former Hitachi Cable News Release

Information (including product prices, product specifications, details of services, launch dates, inquiry information, and URLs) contained in this news release is current as of the date of the press release but is subject to change without notice. Please note that details may differ from those effective on the search date.

Development of the World's First Corrosion-resistant Metal Separator for Direct Methanol Fuel Newly developed separator successful in starting up DMFC stack - downsizes stack to half conventional graphite type

Hitachi Cable, Ltd. has developed a corrosion-resistant metal separator*2 for direct methanol fuel cells (DMFC)*1, which are attracting attention as a next-generation power supply for mobile devices. This metal separator is the first of its kind in the world. In collaboration with Hitachi Research Laboratory, Hitachi Ltd., Hitachi cable succeeded in starting up a DMFC stack using the new metal separator. Through the use of the metal separator, this DMFC stack is made smaller in size and lighter in weight. A laptop computer can be droved with an output of 20-W class using a fuel cell stack of 135 mm x 74 mm x 38 mm.

A fuel cell is a means of generating clean power. It produces power with hydrogen ions, using the reverse reaction to electrolysis of water.

A separator is one of the main components of a fuel cell. The separator must have high corrosion resistance to withstand the operating environment, and low resistivity to increase power generation efficiency. Graphite meets these requirements, and precision-machined graphite products are widely used as fuel cell separators. Some problems still remain, however, with regard to graphite; one of which is its low impact resistance. As a result, the graphite separator must be made sufficiently thick. In addition, the precision machining involved is extremely costly.

DMFCs, which use methanol to generate hydrogen ions, are now in increasing demand as a power supply for mobile devices, as they are easier to handle than hydrogen fuel cells (PEFC)*3, which use hydrogen gas. As a result of such demand, a separator for a DMFC is required to be small in size. However, as the methanol environment is extremely severe, for example, causing resin swelling, corrosion and oxidation of metal, no materials other than graphite or a noble metal can be used for the separator.

We have therefore been concentrating efforts on developing a metal separator suitable for a DMFC; one that is highly strong, inexpensive, and sufficiently corrosion-resistant to enable it to withstand the methanol environment. We are the first in the world to have successfully produced such a separator.

This technological development has the following features.

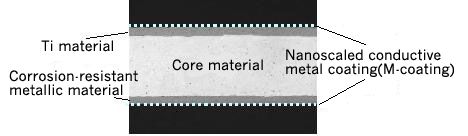

(1) New surface treatment: nanoscaled conductive metal coating (M-coating)

We have succeeded in depositing a noble metal on the nanometer scale on the surface of a cladding material, and then increasing the strength of the surface through our original surface treatment method. This makes it possible to produce a base material that has a highly conductive surface and high methanol resistance.

(2) Corrosion-resistant titanium cladding material

We use a highly corrosion-resistant material, titanium, as the cladding material, in order to improve the corrosion resistance of the cladding material itself. This makes it possible to improve the corrosion resistance of the machined areas that cannot be treated with the M-coating.

(3) Compact, die-formed DMFC separator

Through the use of our original machining technology, we have succeeded in creating a precisely detailed separator using die forming.

These features enable the newly developed metal separator to achieve high resistance to methanol, and low resistivity. When mass-produced, the new separator is expected to cost only 1/50th to 1/100th of that of a conventional graphite separator.

A single fuel cell consists of an electrolyte membrane*4 sandwiched by separators. A fuel cell stack is made up of multiple layers of such cells. With the newly developed metal separator, the separators can be tightened evenly due to the natural elasticity of metal. This prevents the leakage of electric energy, which is likely to occur when cells are layered, and therefore enables good power generation properties to be achieved (Figure 2).

In addition, the size of the stack is reduced to half that of one that employs a conventional graphite separator.

The DMFC stack is still in the development stage. The properties of its components are also expected to be improved drastically in the future. With the development of the new metal separator, DMFC will achieve the size and output required for use with laptop computers.

Hitachi, Ltd., Hitachi Maxell, Ltd., and Hitachi Cable are working together to develop a methanol fuel cell power supply for mobile devices as part of a project subsidized by the New Energy and Industrial Technology Development Organization (NEDO). This report is based on the results of this project.

Glossary

*1 Direct methanol fuel cell (DMFC)

A DMFC is a fuel cell that uses a polymer electrolyte membrane and uses a methanol solution as the fuel. The methanol solution and air are directly supplied to the electrodes in order to produce electricity. This fuel cell is expected to serve as a ubiquitous power supply for personal digital assistants, mobile computers, and the like. It is also an environmentally friendly fuel cell, producing only water and carbon dioxide during operation.

*2 Corrosion-resistant metal separator

The separator is a key component of a DMFC. It serves as a wall to separate the methanol solution from air supplied to the DMFC, and as a frame to form a stack structure. For the separators, graphite has been widely used. If the separator is made of metal, on the other hand, it can be made strong, thin, and compact, its productivity can be increased, and its cost can be reduced. The problem is resistance to corrosion in the environment of the cell. The answer lies with a corrosion-resistant titanium separator. This type of separator is already used for PEFCs. This metal separator has a long life, approximately the same as that of a graphite separator.

*3 Hydrogen fuel cell (Polymer Electrolyte Fuel Cell: PEFC)

A PEFC is a low operating temperature (approx. 70C to 80C) power generator, which uses a solid polymer membrane as the electrolyte. It uses hydrogen as the fuel. Hydrogen is reacted with oxygen in the air, producing electricity and heat (hot water). Manufacturers are developing PEFCs for practical use at home, in the office, and in electric cars. A DMFC is a type of PEFC. They operate at room temperature.

*4 Electrolyte membrane

The development of the electrolyte membrane is a technology central to the development of a fuel cell. This membrane is a polymer membrane, and it separates the fuel electrode from the air electrode. In a direct methanol fuel cell, which directly consumes a methanol solution as the fuel, the membrane must only allow passage of the hydrogen ions produced on the fuel electrode side, and not methanol. The electrolyte membranes currently available, however, are not able to shut out methanol completely, which adversely affects the fuel cell properties.

a.Sectinoal structure

b. Corrosion-resistant metal cladding material

c. Separator

Figure 1. Corrosion-resistant metal cladding separator coated with nanoscaled conductive metal [Fuel cell stack]

Figure 2. Appearance of a DMFC stack (25-W class) using a metal separator and its components